OmniSurf 是 經濟系統的表面輪廓分析(surface profile analysis),可以滿足多種類型的分析需求。

OmniSurf 作為一個表面輪廓分析“工具箱”,包含表面分析的許多最新研發的分析技術。使用OmniSurf,您可以:

- 分析從大多數主要製造商的各種儀器收集的數據文件

- 對多個配置文件執行“hands off”批處理

- 應用最新的計量工具(許多儀器尚未提供),包括:

- 高級過濾方法(新的過濾器和帶通功能)

- 新的、更實用的表面紋理參數(plateaus, conformable surfaces, etc.)

- 將參數結果導出到電子表格文件

- 利用許多圖形分析,包括:

- 承載比

- 材料概率

- 波長成分(傅里葉)

- 基於區域的配置文件分析

OmniSurf details

Operating system and common features:

OmniSurf runs on any 32-bit or 64-bit Microsoft Windows platform and includes standard Microsoft features such as:

» Clipboard output of graphical sections

» Drag and drop file loading

» Standard Windows printer support

» Standardized user interface conventions (menu layout, right click, double-click, etc.)

Data access:

OmniSurf provides for direct loading of files saved or exported from most popular surface texture instruments. Supported file types include:

» SigmaSurf (*.sig)

» Jenoptik/Hommelwerke (*.pro; *.pip; *.asc; *.smd; *.hwp; *.hfm)

» Mitutoyo (*.csv; *.dat; *.mes)

» Form Talysurf (*.prf; *.fts; *.ruf, *.mod)

» Talysurf 10 (*.ten)

» Talysurf 6 (*.six)

» Talyrond (*.str)

» Surtronic 3+ (*.stp)

» Renishaw (*.xls; *.zpx; *.rsf; *.out; *.txt)

» Metrex (*.prf)

» Mahr (*.pcd; *.prf; *.txt; *.pra; *.s2p)

» TSK/Zeiss (*.rst; *.txt; *.tx1; *.tx2; *.nc; *.ynz)

» Federal (*.dir)

» Somicronic (*.pro; *.smd)

» 2Pros (*.hdr)

» BTI (*.csv)

» UBM ASCII (*.pr)

» FRT X-axis Text (*.txt)

» Precision Devices (*.pdi; *.dat; *.nds)

» Standard Data (*.sdf)

» Hexagon Coordinate (*.yz)

» CellView Text (*.txt)

» Jenoptik Evovis XML (*.xml)

» Zygo Profile (*.txt)

» CMM Data (*.out; *.txt)

» OmniSurf Settings (*.ini)

» 2-Column Radius (*.sip)

» Insitutec (*.ist)

» Multi-column SIG (*.sigh)

Parameters:

OmniSurf provides many common surface texture parameters as well as parameters resulting from recent advances in the field of surface metrology:

» Ft Pa Pdsm Phsc Pku Pm0 Pm2 Pm4

Pp Ppc Pq Ps Psk Psm Pt Pv PVc

» Ra Ra1 Ra1l Ra7 Ra7l Rc Rcl Rdmd Rdmn Rdq

Rdsk Rhsc Rk Rk+vk Rku Rm0 Rm2 Rm4 Rmax

Rmq Rmr1 Rmr2 Rp Rpc Rpk Rpk* Rpk/k Rpk+k Rpm

Rpm/3z Rpm7 Rpm7l Rpq Rq Rs Rsk Rsm

Rt Rtwi Rv RVc Rvk Rvk* Rvk/k Rvm Rvo Rvq

Ry Rz1max RzDIN RzJIS R3z

» Wa Wc Wcvx Wcvxl Wcvxm Wdq

Weslp Weslpl Wlslp Wlslpl Wp Wpc Wpl Wpr Wq

Ws Wseg Wsegl Wsm Wt Wtc Wv Wvda Wvdas

Wvdc Wvdd Wvddl Wvdm Wvdmp Wvoid

» AR AW R Rx W Wte Wx

» Bearing Ratios (tpa/tpi, Pmr/Rmr): 10 Primary & 10 Roughness

» Htp Values (PHtp/RHtp): 10 Primary & 10 Roughness

Filters

Standard filter cutoffs are available as well as a variety of bandpass configurations. Filter types include:

» Gaussian

» Spline Based Gaussian (with adjustable tension

» Valley Suppression (ISO 13565-1 – 1996)

» Robust Spline-Based Gaussian (based on robust regression)

» Morphological Closing Filter (circular element applied to waviness profile)

» Morphological Opening Filter (circular element applied to waviness profile)

Form removal options:

» Instrument reference (mean suppression)

» Least Squares Line

» Least Squares Arc

» Fixed Radius

» Least Squares Polynomial (user specified order)

» Spline Filter (for bandpass waviness with a user specified cutoff)

» Asphere (user defined coefficients with optional radius optimization)

» Free Form (user defined coordinates with optional pre-filtering)

Data export

OmniSurf allows for the export of computed parameters into a Comma Separated Values (CSV) spreadsheet. Subsequent analyses are appended to the spreadsheet as rows thereby allowing for the analysis of groups of data. In addition, OmniSurf allows for the export of several profiles and curves related to the data. These are exported as ASCII files and include

» Direct (Raw) Profile

» Form Suppressed Profile

» Primary Profile

» Waviness Profile

» Roughness Profile

» Wavelength Content (Spectrum)

» Primary Bearing Ratio Curve

» Primary Amplitude Distribution

» Roughness Bearing Ratio Curve

» Roughness Amplitude Distribution

» Asphere Sag/Residual Table

» Morphological Closing Profile

» Morphological Opening Profile

“Hands Off” batch processing

Often engineers are faced with the need to process several profiles as part of a production “batch” or process/product study. OmniSurf includes a “batch processing” feature whereby an entire folder of data can be automatically processed with the current analysis settings. OmniSurf will automatically load all of the files in the specified folder and export the results to a spreadsheet file along with exported profiles and graphics.

OmniSurf’s capabilities speak for themselves through the following case studies…

Case Study #1 :: Plateaued (stratified) surfaces

A rather common yet critical type of surface texture is that which is referred to as “plateaued”. These surfaces are found in a variety of critical sealing applications and are identified by their smooth plateau regions that are separated by relatively deep valleys.

In addition to improved filtering methods (see Case Study #2 below) OmniSurf incorporates parameters and graphical output for the ISO 13565-1996 Rk family of parameters (Rk, Rpk, Rvk, Mr1, Mr1 and Rvo) as well as graphics and parameters for the ISO 13565-1998 probability based, Rq, parameters (Rpq, Rvq and Rmq).

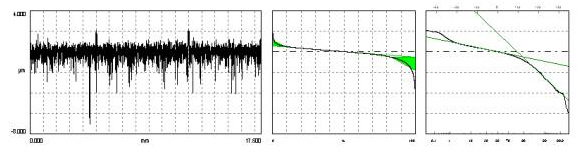

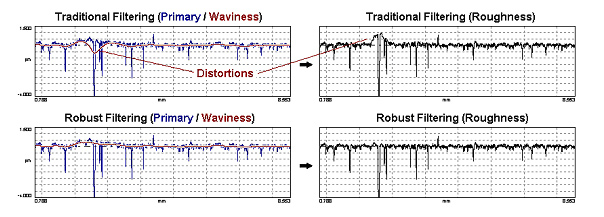

Case Study #2 :: Filtering for porous surfaces

Many production measurements of surfaces can be strongly influenced by extraneous peaks (debris) or valleys (pits, pores, etc.). These extraneous features can cause significant distortions in the waviness profile and can corrupt many roughness and waviness parameters. OmniSurf incorporates the “valley suppression” filtering methodology put forth in ISO 13565-1996 as well as a new “robust filtering” approach. This robust filtering technique provides a more stable and functional meanline (without the unwanted distortions) and as a result gives more meaningful roughness and waviness profiles and values.

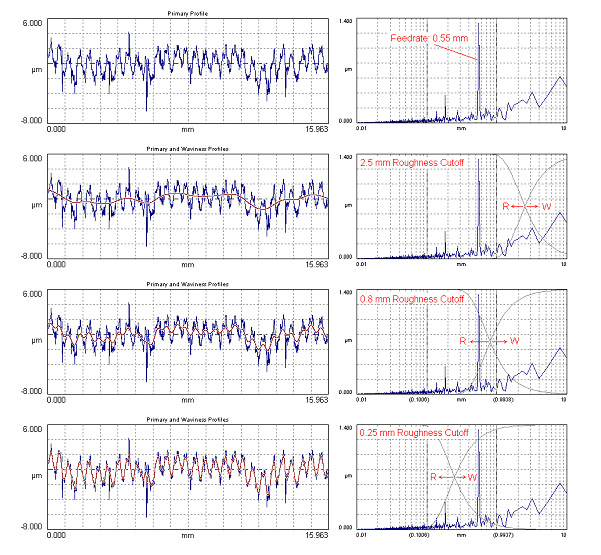

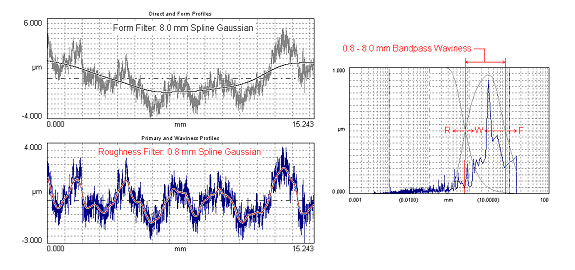

Case Study #3 :: Filter cutoff selection

When surface roughness or waviness is reported there is an implied distinction between long wavelength waviness and shorter wavelength roughness. This distinction is made mathematically in terms of a cutoff wavelength (or “roughness cutoff”). According to ASME Y14.36-1996 “…drawings …shall state the roughness cutoff”. However, many product engineers and designers struggle to determine the proper cutoff for their surfaces. OmniSurf provides two tools to aid in the selection of a roughness cutoff wavelength.

The first tool is the simple display of the waviness profile overlaid on the primary profile. This display provides the user with a graphical display of the waviness and the ability to visually assess how well the waviness profile “fits” the underlying shape of the surface. The second tool regarding filter cutoff selection is wavelength content graph with the filter transmission characteristics superimposed. This unique graph exploits wavelength regimes in the profile and their relationship to filter cutoffs.

Case Study #4 :: Conformable interfaces (for example, gasket applications)

Many critical surfaces are in systems whereby they are in contact with a conformable component such as a seal or gasket. In these cases, certain shapes can be accommodated by the conformable component whereas other shapes can lead to performance problems such as leakage.

OmniSurf provides two analytical approaches for analyzing surfaces in contact with conformable counterparts. The first of these capabilities is known as “bandpass waviness”. In this approach, the long wavelength “Form Errors” can be extracted through using the “Spline Filter” option as the “Form Removal” method. The cutoff of this form removal filter can be selected based on the compliance of the conformable component. The peak to valley assessment of the “form profile” is then reported as “Ft”. Similarly, the waviness and roughness profiles can be characterized though other conventional parameters.

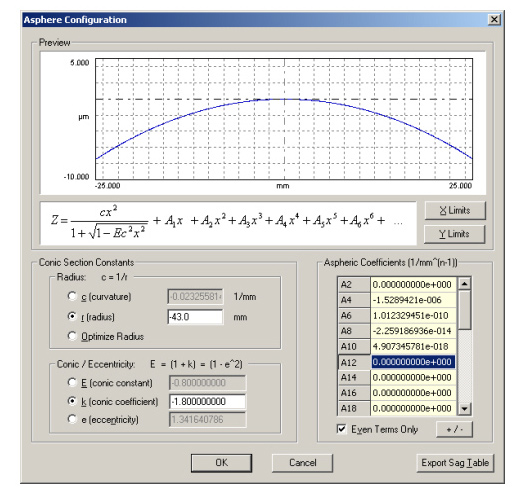

Case Study #5 :: Aspheric form analysis

Many critical optical surfaces are aspherical in terms of their form and are defined by an equation combining of a conic section and an nth order polynomial. These sophisticated geometries are required in important optical applications such as telescopes, optical instrumentation, cameras and contact lenses.

OmniSurf includes the ability to analyze aspheric surfaces and provides an intuitive interface for the configuration of the aspheric reference geometry. The OmniSurf asphere configuration utility supports clipboard cutting and pasting for the asphere’s coefficients as well as a scalable, live preview of the aspheric form. In addition, the Sag Table can be exported for use in other applications.

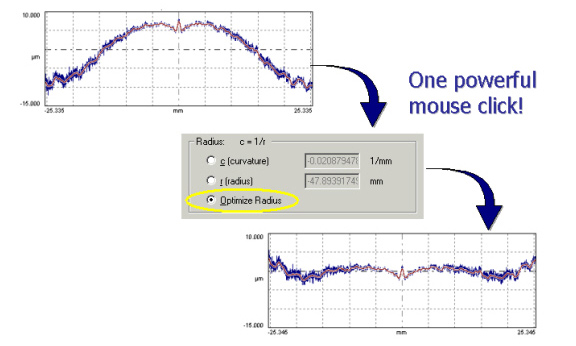

Typically, the analysis of aspheres involves measuring the component and looking at the residual form error. Usually the majority of the resulting form error is the result of an error in the component’s base radius. To determine the actual (measured) the base radius, the operator manually adjusts the nominal radius and re-analyzes the data until the residuals look acceptable.

One of the most powerful aspects of OmniSurf’s aspheric tools is the ability to automatically determine the optimal aspheric radius based on the measured data. Look at the dramatic change in the residual profile – all with one simple click of the “Optimize Radius” button!

HatchView

HatchView turns your USB microscope into a high-powered, easy-to-use crosshatch analyzer.

With HatchView you can:

- Explore your bore while computing cross-hatch angles in real time

- Save images with or without the crosshatch calculations for product documentation

- Analyze crosshatch angle per the 4 most common methods.

HatchViewSPC

HatchViewSPC turns your USB microscope into a high-powered, easy-to-use crosshatch analyzer.

With HatchViewSPC you can:

- Explore your bore while computing cross-hatch angles in real time

- Save images with or without the crosshatch calculations for product documentation

- Analyze crosshatch angle per the 4 most common methods.

- Export results to your SPC system with a simple push of your camera's shutter button

- (Results can be exported to a file or transmitted via RS-232.)

OmniRound

OmniRound – an roundness/circularity analysis package designed for the most demanding analytical needs.

With OmniSurf you can:

- Analyze data files collected from a variety of instruments from most major manufacturers

- Apply the latest metrology tools (many are not yet available in instruments) including: Advanced filtering methods (new filters such as “robust” filters and bandpass capabilities)

- Export parameter results to a spreadsheet file

- Explore & Export Harmonics

- Compare various reference circles

- Perform “hands off” batch processing of multiple profiles

OmniSurf3D

OmniSurf3D – 3D surface texture analysis made easy!

OmniSurf3D is a surface topography “toolbox” encompassing many of the latest developments in surface analysis. With OmniSurf3D you can:

- Analyze data files collected from a variety of instruments from most major manufacturers

- Perform “hands off” batch processing of multiple surfaces

- Apply the latest metrology tools (many are not yet available in instruments) including:

- Advanced filtering methods (new filters and bandpass capabilities)

- Standard and specialized parameters

- Explore and measure profile sections

- Send profile data to OmniSurf (2D) with one click (sold separately)

- Send profile data to OmniSurf (2D) with one click (sold separately)